I have recently bought an old e-bike built by Batavus, the e-go (see here for a review in Dutch). The bike is equipped with a Panasonic mid-drive motor. The motor did not run, even with a power supply connected instead of the defect battery. I therefore decided to open up the casing and see if I can find faults in the PCB.

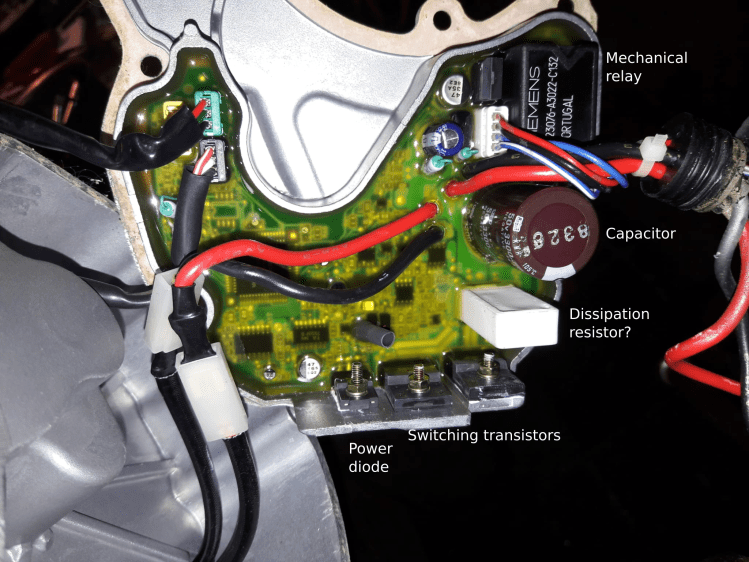

To my surprise, the PCB employs a mechanical relay. It was about the only component that I could reach due to the epoxy, and it seemed to be the one component that is failing, as well (lucky me). When hard-wiring the connections of the two poles in the relay, I could get the motor back to life…

Torque sensor

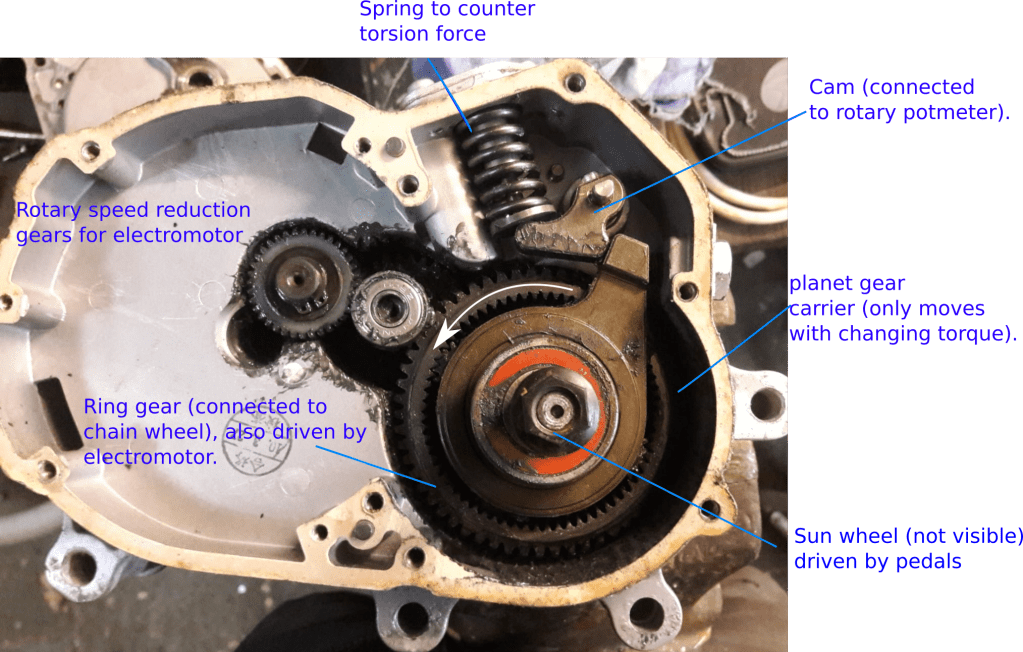

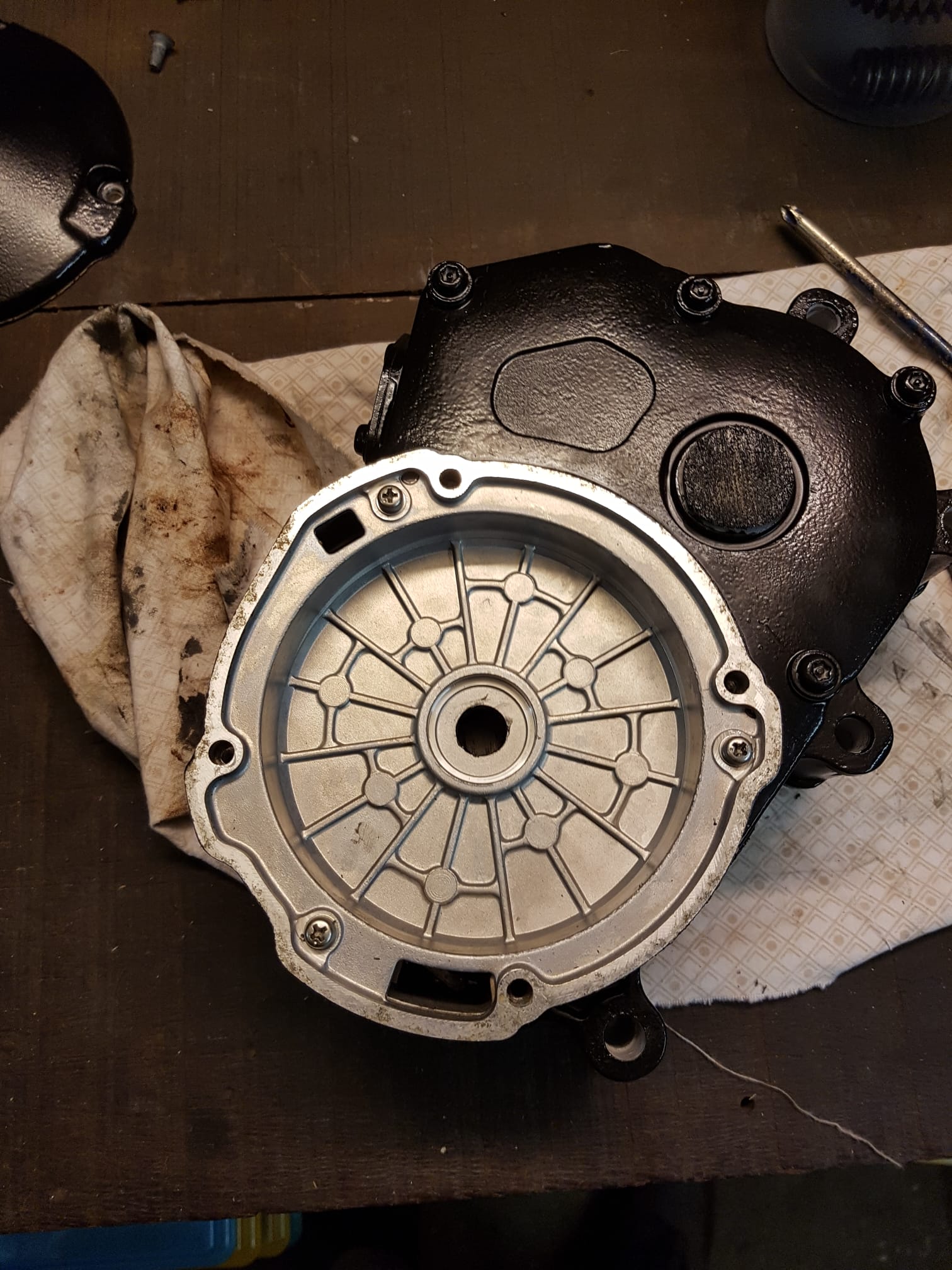

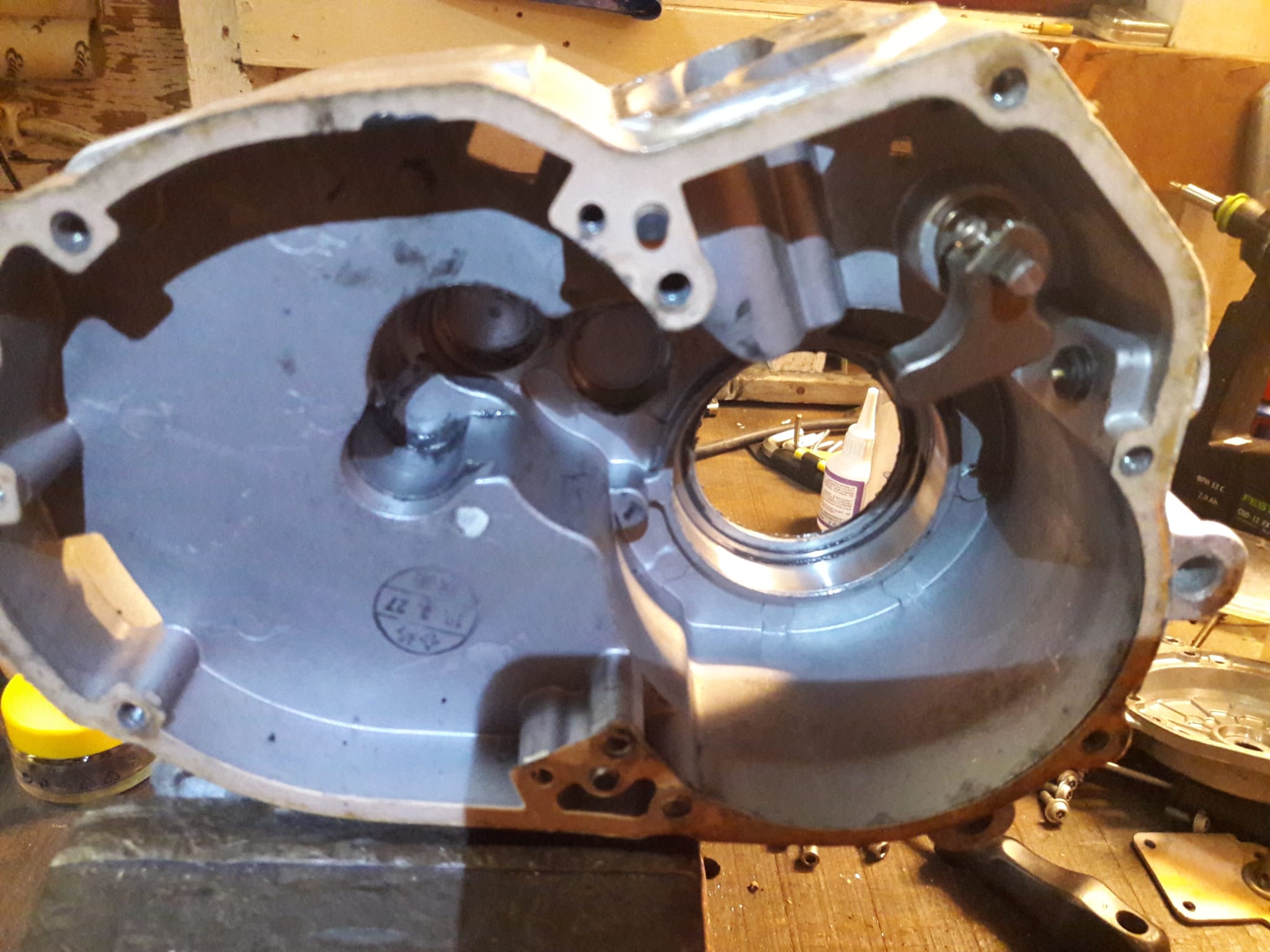

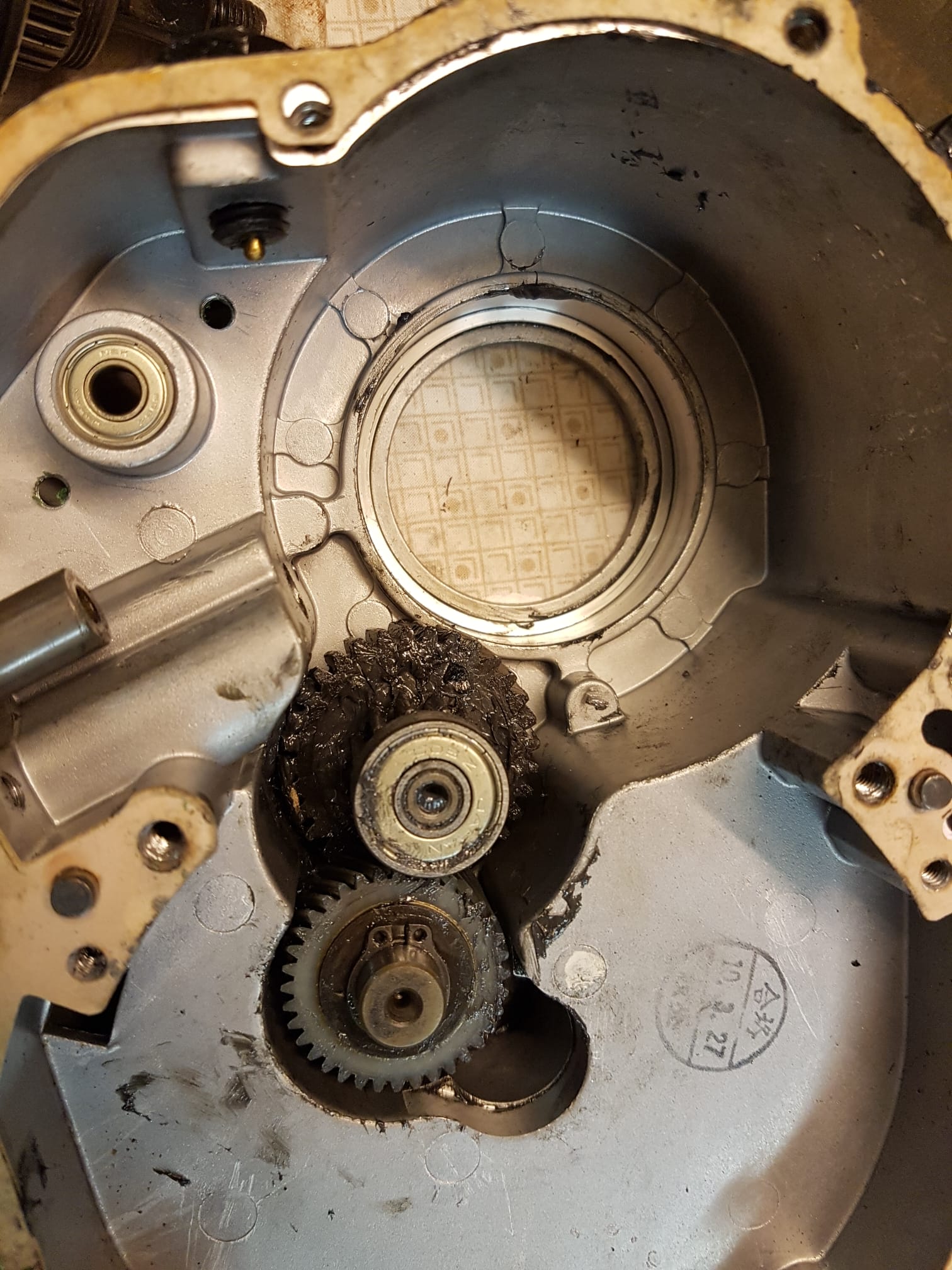

This mid-drive motor increases the rotary speed of the pedal axle to the chainwheel by using a planetary gearset. Doing that, it cleverly uses the planetary gear carrier in a semi-stationary way: it only rotates a few degrees due to torque applied on the pedals. This pushes a spring-loaded cam. The camshaft is directly coupled to a rotary potmeter, which is read out by the PCB. Very simple and elegant solution!

The first gear connected to the DC motor (most left in the picture above) is made of plastic, so could be prone to wear. The motor gear has a helical shape, to allow for a very small first gearwheel, as used in modern Bosch motors as well (explained here).

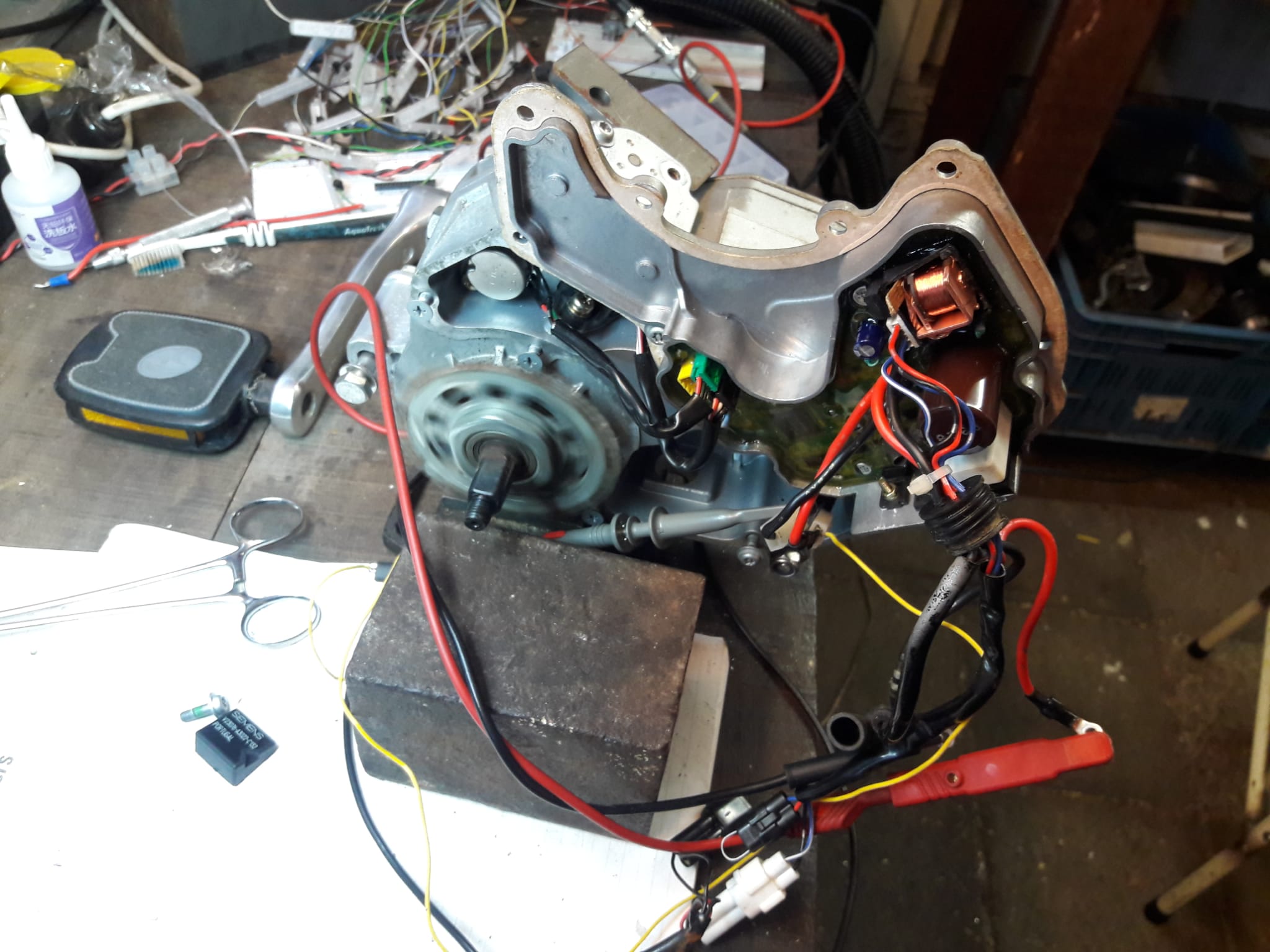

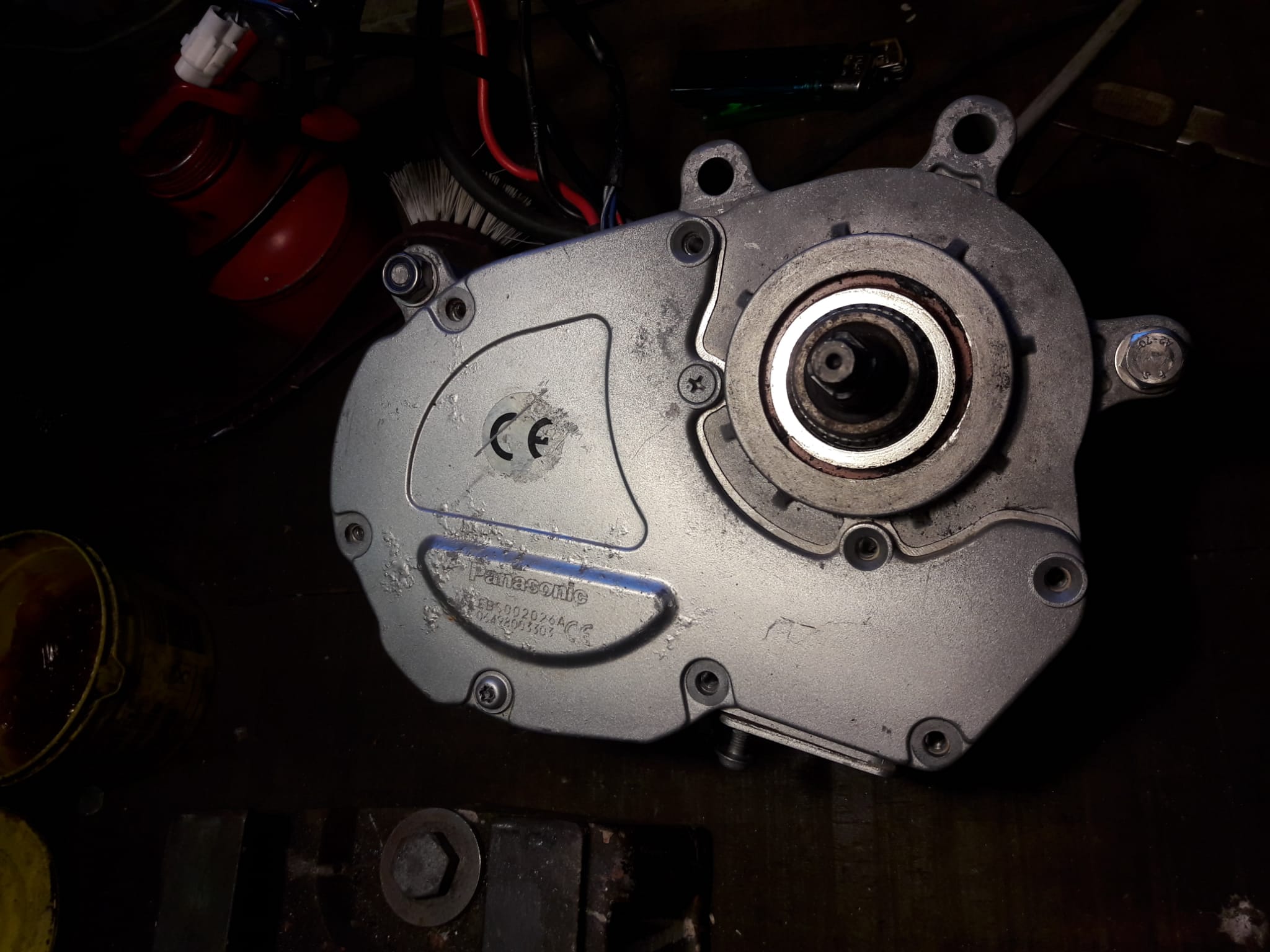

Some more pictures

I will update this post when the motor is built back into the bike.

Leave a comment